What are the characteristics of high-frequency welded aluminum strips?

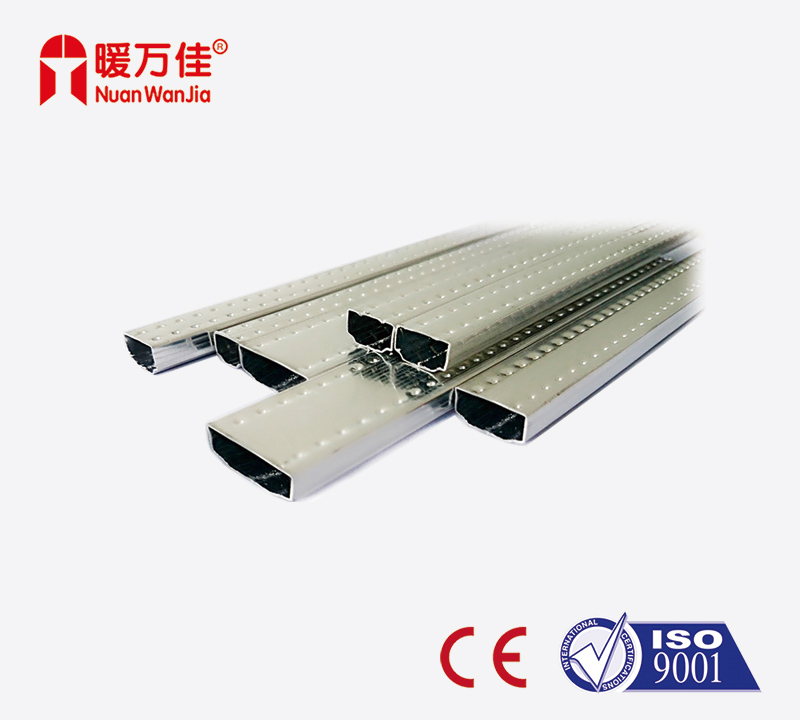

Release date:2021-10-19Page view:5817Hollow aluminum strip is one of the necessary materials for the production of insulating glass, and its quality is directly related to the use effect, service life and thermal insulation function of insulating glass. Its main function is to evenly separate the two sides or more pieces of glass in the insulating glass and effectively support it. So what are the subtle differences between the high-frequency welded aluminum bar and the ordinary aluminum bar that belong to the hollow aluminum bar?

The global aluminum network introduces the difference between high-frequency welding aluminum spacer (aluminum bar) and ordinary aluminum bar as follows:

1. Compared with ordinary aluminum bars, high-frequency welding aluminum spacer bars (aluminum bars) have the following advantages:

1, anti-rust, anti-corrosion, high brightness

2, the face of the aluminum strip is even, the straightness is good, no deformation, and the size is stable

3, high strength, good toughness, can be combined with bending equipment continuous bending into any Angle of aluminum frame

4, to ensure the activity of molecular sieve, to ensure that all kinds of adhesives have excellent adhesion

Second, the advantages of high-frequency welding aluminum spacer bar (aluminum bar) used on insulating glass:

1, the ordinary aluminum strip uses four connection angles to make insulating glass, the insulating glass made of four corners of the edge sealing effect is poor, the most easy to leak, water permeability, easy to cause insulating glass failure, shorten the service life of insulating glass.

2, the high frequency welding aluminum bar is made of insulating glass with continuous Angle connection, the insulating glass made of four corners without connecting parts, the sealing effect is excellent, not easy to leak, permeable water, and extend the service life of insulating glass; At the same time, its performance and performance can be comparable with similar foreign products.